The yard was meant to have done all of the reinstallation work last week, so I went up to Malahide on Saturday to take a look at the progress. Turns out that while indeed the engine is back in, and the fuel filters are installed, the diesel tanks are just sitting in placed without any of the connections put back. So, phone call on Monday to the yard, with a “I’d like to launch on Friday, is that feasible?” request.

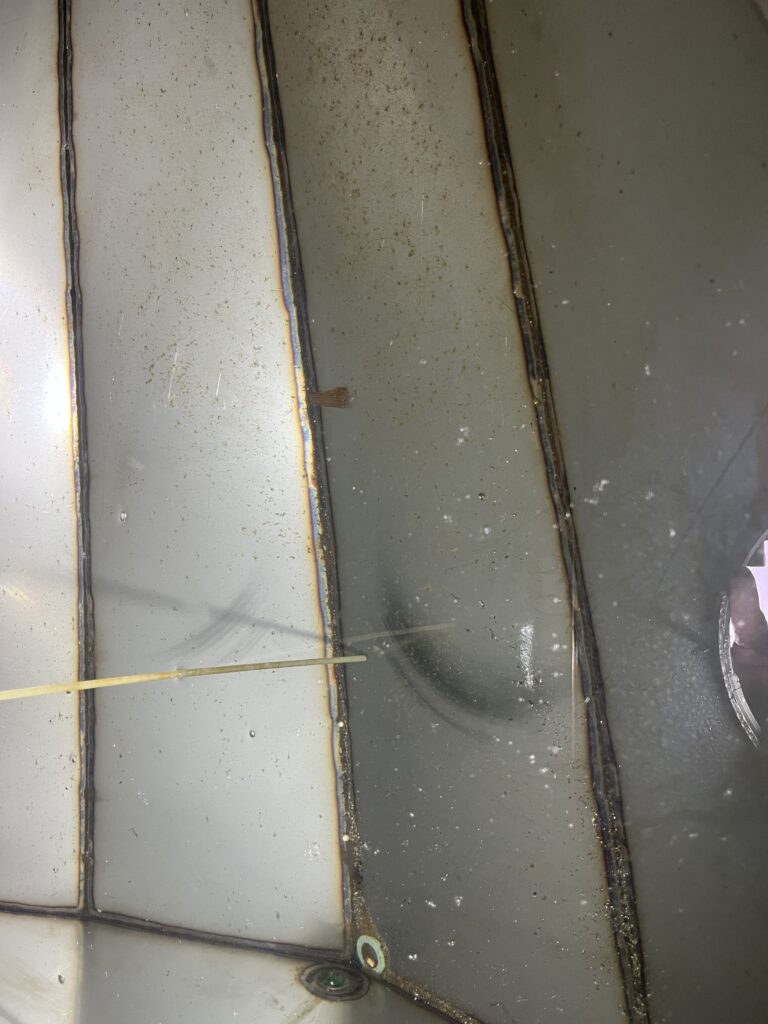

On the plus side, they did get the access hatch installed, and it works really well, giving me access to the innards of the tank in a manner that doesn’t mean undoing 20 screws and re-doing a bunch of sealant. The tank looked pretty clean, though there was a definite green/brown scum on the tank walls, plus all the swarf from cutting the access hole.

With a lot of muttered swears at the recalcitrance of hoses to release from barbed connectors, I managed to get the feed from the tank disconnected and looped back down to the limber hole that’s at the bottom of the tank area, and the water started to flow to the bilge. This let me test the automatic bilge sensor – it’s a field effect type one – and it’s still working just fine. With the tank drained, I wiped down as much of the inside as I could with a big sponge, and cleaned up most of the swarf and detritus. A proper clean can be done later, preferably with something like a pressure washer.

Getting the floor panel up in the master cabin took a moment of thought – I checked some of the gaps, and the feeler gauge at 0.05mm wasn’t thin enough to fit. Turns out if you put one of the screws back in to the metal fitting and pull gently(ish) with pliers, the corner comes up and then the whole thing comes out. I had been curious why I was getting water on both sides of the mast foot, and with the floor panel up it was possible to see that there are two limber holes. I wiped out all the crud, let it dry, and put the floor panel back.

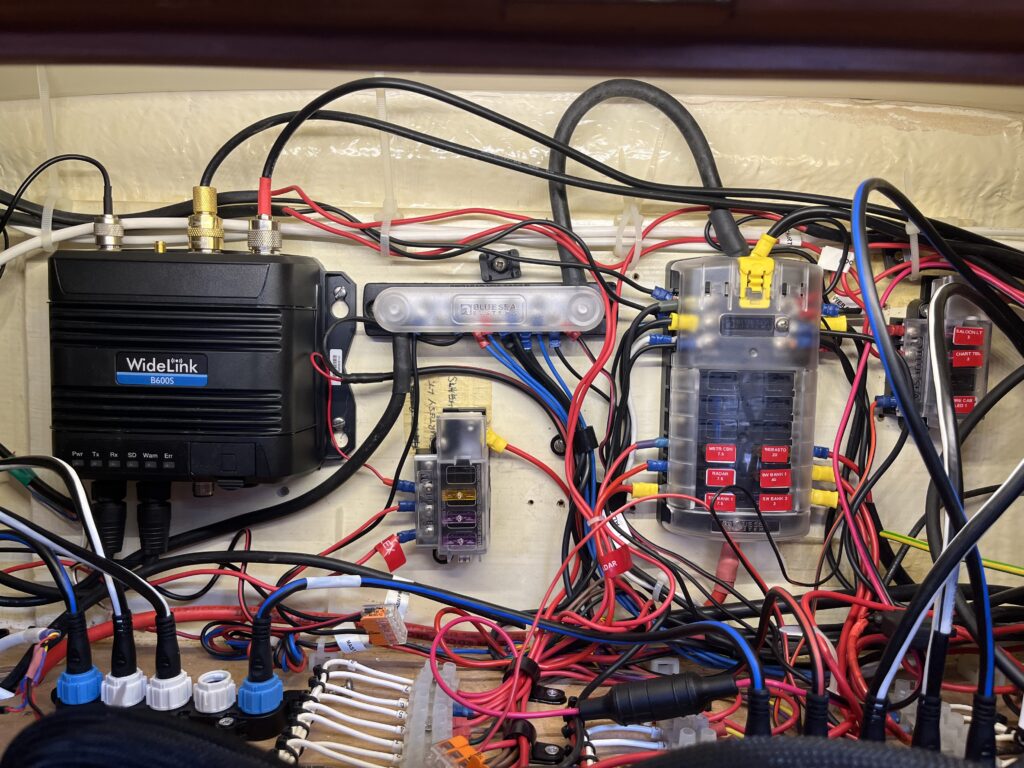

I then spent a few hours poking the wiring cabinet to put fuses on the wires to the various bits of equipment that were connected through Wago connectors. This necessitated moving a negative bus bar from vertical to horizontal, replacing fork connectors with ring connectors, moving negative cabling around (and doubling connections on one or two terminals – both sets of cabin light wires now connect to the same negative terminal), and then fitting another Blue Sea Systems 4-fuse block. As usual, the cabinet back is just far enough away that stretching my arms out doesn’t quite work, but getting up and kneeling on the saloon berth means contorting myself under the deck overhang.

The fuse block is fed to the terminal block that’s run through the instruments switch, so the Miniplex, B600S, and SeaTalkng bus power (so transducers and course computer) all turn on with one switch. VHF continues to be separate, as does the autopilot ACU. I also remembered to flip the power switch in the ACU to off, so it stops feeding power to the bus.

With the ACU duly adjusted, I put back the door to that locker/cabinet. There are four screw holes on the inside that make me wonder what might have been installed on the door before – toilet paper holder?

The master cabin door has been sticking for a while. I fettled it a bit, and determined with the feeler gauge that the door is binding about 4 cm above the handle/lock area, for a good 5 cm.

The hinges are flush mounted on the door, but surface mounted on the frame. I reckon if I mark the edges of the fitting, then chisel out the frame by half-to-full depth of the hinge that I’ll fix the binding without introducing other issues. There’s plenty of clearance on the door around on the hinge side. Not urgent, but I know what needs to be done at least.

The lock plate was also interfering with the strike plate, and a visual inspection showed the lock assembly was bent in two different directions – the lock body wasn’t at 90 degrees to the plate, and the plate was bent at the ends. A bit of force was applied, and then I put the lock back in and changed the screws to get a bit more bite in the old plywood core. This resolved the interference, though the door itself still binds.

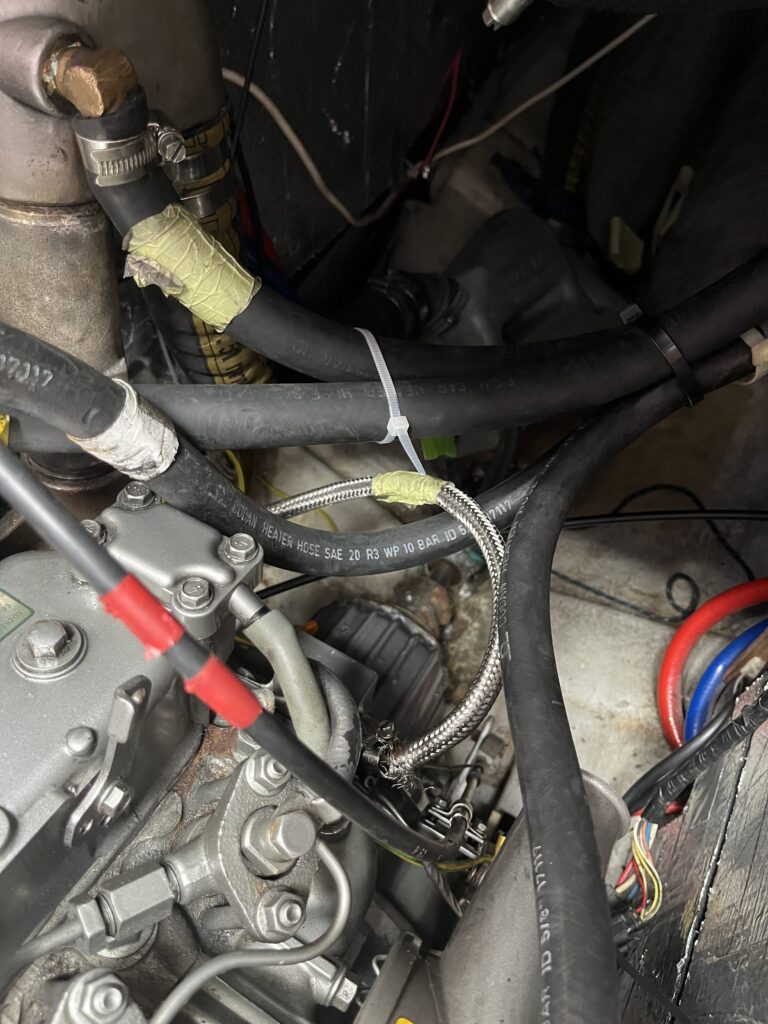

The new filter layout looks pretty good, and they’ve used some Vetus mechanical fixings to hold the insulation in place over the prop shaft. I question the over/under arrangement of the coolant hose and diesel return hose, but I can move the coolant hose easily enough.

Blue Opal has been away long enough that people at the club have been wondering if I’m still alive! Hopefully that will change at the end of this week, and K and I can finally go sailing. Just need to find the winch handles…