Since the renovation in 2019, the cylinder-fed hot water supply in the house has had air in it. Constantly. Every day. So I’d go to take a shower, and have to clear a bunch of air out of the feed before the shower would be happy. Worse, it would occasionally feed air mid-shower too, which was odd.

I finally got around to asking a plumber to look at it (and a few other things). We spent over an hour poking around and discussing what might be going on, and after I found the build/renovation photos, we were able to test a hypothesis. Namely, there was an expansion pipe from the hot water tank, feeding back into the cold water tank. We extended the expansion pipe until the end was into the water in the tank, and I turned on the shower – air for a bit, then the shower pump settled down, and failed to produce a hot shower because it was sucking water from the top of the cold water tank!

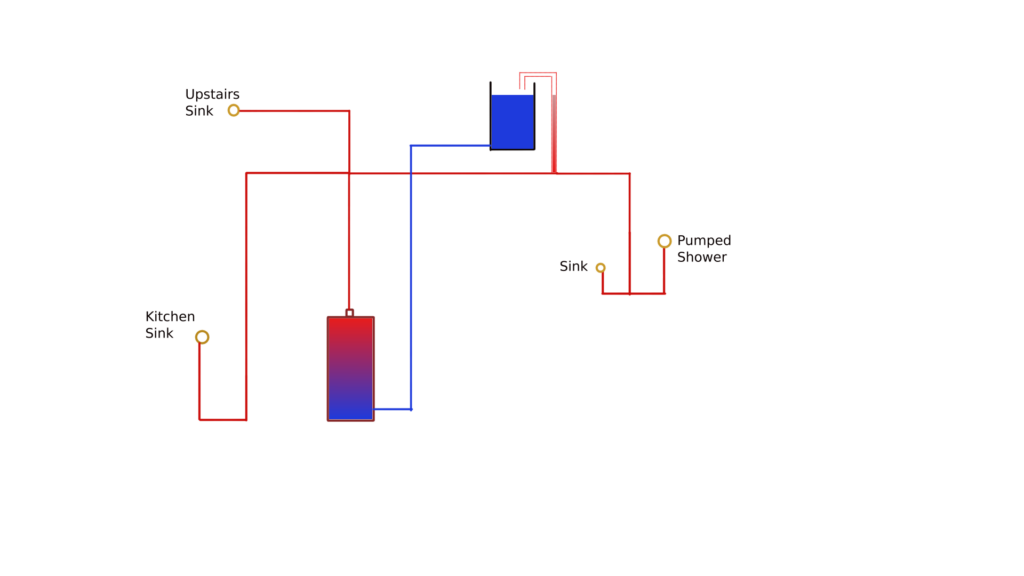

This draw from the top of the tank indicated that we were probably dealing with an imbalance in the head pressures – indeed, the air only ever really appeared in the mid-level bathroom and slightly in the kitchen, never in the guest bathroom upstairs. In both cases, the head pressure from the expansion pipe to the outlets was higher than the pressure from the cold tank to the cylinder and back up to the outlets. This resulted in air being pulled in via the expansion pipe, with the pumped shower being the most affected because of the volume of water it was moving. (Diagrams are not to scale, but are close enough.)

This experiment, plus the photos, led to the conclusion that Gas Safe’s install in 2019 was done incorrectly; a hot cylinder should have an expansion/return pipe coming straight out the top, and the hot water supply should tap off of the side. The installation in 2019 took a single pipe off of the top of the cylinder, ran it to just under the cold tank, and then split it so that hot water could go to the mid-level bathroom, and the expansion could be returned to the cold water tank.

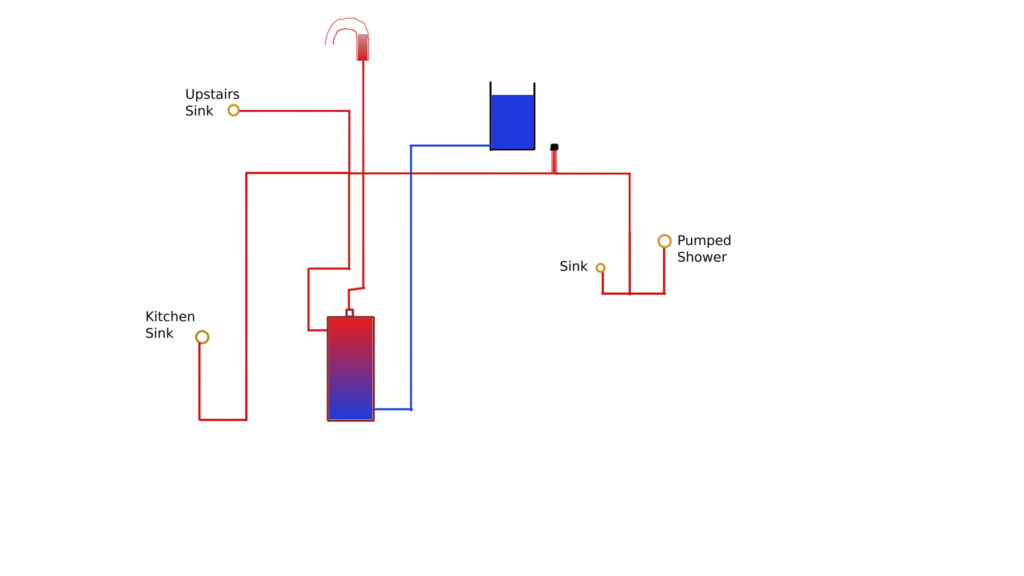

The solution was to do the correct split at the cylinder, with the expansion pipe running from the top of the cylinder, out the wall, and up the side of the house – it could have been done properly (inside the house, up to the cold tank) when the house was torn apart for renovations, but it wasn’t. The return to the cold tank was capped off so that it can’t feed air into the hot water pipes; if I were to take off the cap and turn the handle, water would fountain out (so it needs a label).

We tried tucking the new expansion pipe under the soffit, but it turns out the water level in the tank was still just every so slightly higher than that, so there would have been a constant trickle of water being pushed out, and thus a constant trickle of cold water into the hot cylinder. Thus, we ended up routing it so that the pipe curves over onto the roof.

The plumber (SM Precision Plumbing) also

- sorted out a weep in the bathroom radiator (new valve needed) that was causing air to get into the system, with the end result of needing to bleed the topmost radiator every month or so

- replaced a leaking, crusty gate valve at the back of the bath; wasn’t a bad leak, but he was here, and it was there, so fix it

- tightened up the bath hot faucet that had come loose and was spinning

- replaced the high pressure mixer tap in the guest bathroom with a low pressure one, improving the flow of hot water

- hooked up the cold tap of the mid-level bathroom to the mains, instead of the cold tank; leaving the cold tank to supply the hot cylinder, and the mid-level toilet

Very happy with the quality of the work done – Stephen was neat, and tidied up after himself. He was happy to investigate and test hypotheses about what might be going on with the piping (and finding the build photos was definitely helpful here).