Blue Opal is a master cabin setup Victoria 34, which means all of her electrical buses (and instruments) sit over a chart table that’s sandwiched between the aft heads and the starboard saloon berth (the wet locker on the other layout isn’t present in this variation, though there’s space in the heads to do so). The access space isn’t great when you’re over 6 feet tall and have broad shoulders – it’s a general case of everything needs to be 5 cm closer, or the access panel 5 cm wider and taller…

Anyway, I’ve been pondering how to get more wiring up into the cubby, so I can add power to the master cabin in the bow. Part of this has been easy – there’s trunking laid in under the saloon berths, and holes already cut to route through the bulkheads. However, once I got to the aft end of the saloon berth, the wiring vanished up a hole that seemed to go in behind the paneling of the boat, and the screw and mastering layout seemed to indicate that I’d need to drill out a lot of teak screw covers to remove the skirtings under the chart table.

As I was looking at the problem a day or so later, I noticed the glint of a screw head inside the aft panel of the after starboard locker in the saloon. Unscrewed three screws, removed the backrest/locker door, started to sing at the boat, “C’mon you bugger, you’re going to swing free for me” (sung to a slightly jazzy tune), and thumped the panel repeatedly with a rubber mallet.

The aft locker, door removed

One of the screw holes visible, and after being hit with a mallet. Repeatedly.

Ducting and wires! The ducting is in tight at the bottom; it won’t pull out easily to make the wiring access easier.

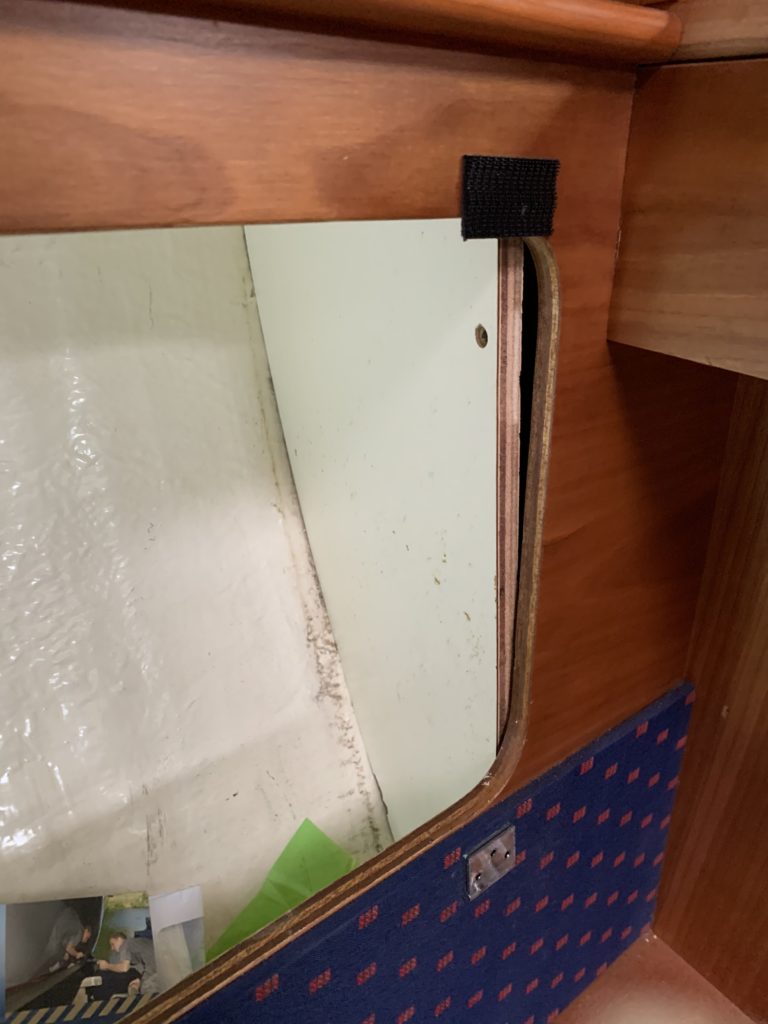

Peering behind the chart table

Magically, I picked the side of the panel that wasn’t braced, and the whole thing slowly swung open like a vault door – I’ll be drilling a finger hole to make it easier to open up in the future.

The chart table is attached to a nice bit of wood with two hinges. With the side panel off, I discovered that the piece of wood runs all the way to the hull, or at least within 1 cm or so. This is problematic, because the wiring cubby is a good 5 – 6 cm above the chart table surface, and has a vertical bit of wood hiding the void behind (and it didn’t want to move).

The answer was some rough measuring with a ruler, some 3D spatial math, and a 40mm hole cutter. Estimated where the vertical panel would be, estimated where the cubby would be, pushed everything up and inboard (where the white cabling is coiled), and drilled at a slight angle up into what I hoped was a void above and behind the chart table.

I then did some more 3D spatial guessing, and drilled down from inside the cubby.

The resulting plugs

Not bad for a space I couldn’t see

Hadn’t come quite the whole way through, which explained why the lower plug didn’t want to move

Not bad really. About 1 cm out on the alignment overall, which for blind drilling is pretty good in my books. The marine ply is really nice quality wood in the core samples that were produced.

I’ve now got the power line for the bow brought up through that hole (the aft one is full), and I can move all the runs from the battery to come up through this hole too. Added a second negative bus bar, because the existing one is oversubscribed, and joined it to the existing one with some 2.5 mm2 wire for now; I think I’d prefer a 4 mm2 cable to join the buses.