Sunday dawned. The forecast said there would be rain in the afternoon, and the tide wouldn’t be right until about lunch time to be alongside for power (to do a different job where we needed to run the multi-tool). Today was to be the day we made sure the seacock would close fully, the old hoses would be removed, and the new Vetus non-permeable hose would be installed. If all went well, we’d have the head re-installed by the evening.

The seacock was pretty recalcitrant, requiring lots of brute force to open/close, open/close until it would actually go to what looked like a fully closed position. This seacock was supposedly greased when I bought her, but has always been difficult to move.

We also took out the old Whale pump while on the mooring, which was pretty easy to do once we found the right size ring spanner. I contemplated keeping it briefly as a backup for the new electric pump, but decided I really didn’t want to try and keep a pump that had been used to move human waste around, even if it had been flushed with Dettol.

With the old pump out of the way, the new one could be fitted. Given the size of the head compartment, the only answer was to contort myself, offer up the pump, mark the first screw hole, remove the pump, drill the starter hole, and then try to hold the pump with one hand and the screw and washer and screwdriver with the other. Surprisingly, with a bit of muttering and cussing, it worked, and the pump went on.

Alongside, and the waste to seacock hose was removed, and we discovered that the seacock does not actually close all the way. Whipped on the bit of hose we’d been using on Friday, and that let us get on with the job.

We took an opportunity to sit in the fully fresh air (and sun!) to clean the head completely, and use the Jabsco spares kit to replace the non-return valve (joker valve) in the outlet elbow and the diaphram from the bowl to the bottom of the mechanical pump. This is now the new location for the head, making it easy for the skipper to use in foul weather.

Unfortunately, I don’t have any 19mm hose, so we’re going to have to keep the old white inlet pipe for now.

Now began the work of all the cutting of the Vetus hose. It’s very easy to cut with a sharp boxcutter type knife, right up until you hit the double helix steel wire. After a while, you get the hang of cutting right up until the blade hits the wire, then rotating the hose a bit, and starting on the other side of the wire. A pair of heavy-duty pliers with integrated cutting blades will go right through the helix wire, complete with spark every time.

We tried a hacksaw, as I’d seen in a forum, but it really doesn’t work well; I actually managed to slice along the axis of the steel wire, and the 24 TPI blade did not like the rubber at all.

We had initially installed the elbows on the pump both pointing away from the pump, and at a slight angle, thinking we’d need the angle to make it easy to install on the bulkhead. We were wrong. The Whale elbows are a very tight fit, requiring the elbow to be heated in boiling water before being shoved over the pump end.

Of course, this meant we had to unscrew the fitting from the pump to re-heat the elbows, and then apply brute force (grip the elbow in one hand, the fitting in the other) to rotate the elbow to a more vertical position. A tip here is to use a sharp knife to make a mark showing the current alignment, so you can tell when you’re getting the damn thing to move.

The next problem was that the pressure of trying to get the pump outlet hose to go down, around and back on to the Y would put a lot of stress on the Y fitting and probably on the elbow fitting. It finally twigged that we could apply the same heat trick to rotate the elbow 180 degrees, and take the pump outlet to Y fitting up and over the pump. The pump doesn’t get hot, so it’s not a problem.

Putting back the head was where the length we cut off on Friday came back to haunt us. No matter how I ran it, it was 5 cm too short for double-clamping to the back of the head. We pulled the bit of 38mm pipe from the old run to the old Whale pump in the starboard locker (two 38mm hose runs joined with a bit of cheap plastic pipe), and bodged a solution for now. I need to measure it carefully, and order more hose to do a proper replacement.

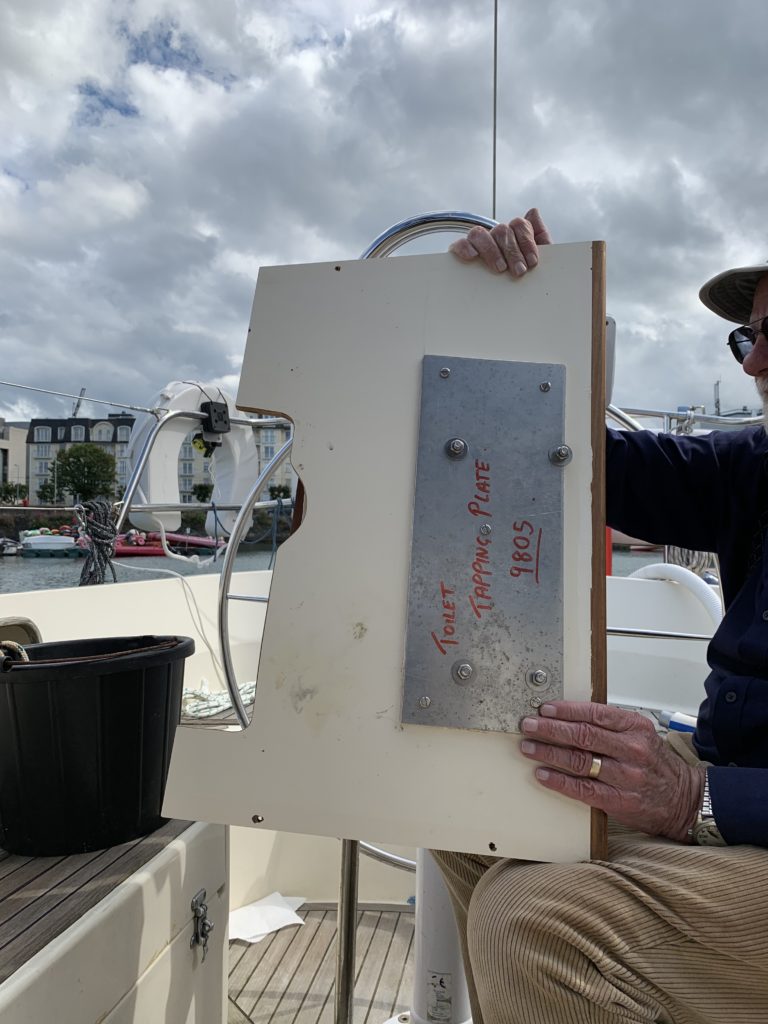

While the cavity that holds the hose was “empty” (it still had all the bow <-> stern cables and the heating duct in it), I took the opportunity to clean it with Ecover and Dettol, and then pouring in a West System + colloidal filler to smooth over an area that could trap water and not let it near the limber hole that’s cut in to the bottom of the inside panel.

With everything back in place, we did the first test pump of the head, and promptly heard a hissing/gurgling that hadn’t been there before, and water started dripping from the join of the outlet elbow to the back of the mechanical pump.

That fitting is not keyed; it’s a simple pair of wide thread screws that pull the back diamond plate against the matching diamond on the pump, and compress a rubber non return valve against a raised ring on the back of the pump. When I fitted it the first time, I had already fitted the outlet hose to the outlet pipe, and then tried to hold everything in place while tightening up the screws.

The fix for this hiss and gurgle was to take it all apart, look at it, and put the elbow fitting in place first, ensuring the seal looked good. The fit the hose over the end with some grunting, tighten up the jubilee clips again, and pump again. Hooray, no water there!

However, now there’s a hiss/gurgle at the top of the diverter valve. Looking at it carefully, it seemed like I hadn’t tightened up the hose clip properly, and the hose wasn’t fully on the elbow; the Vetus hose is a bit thicker than the old white hose, and was bouncing off of the jubilee clip that clamped the elbow to the diverter valve. Of course, the head of that clip was facing the panel that the diverter was mounted to, so no nut driver etc would get in there – simple spanner in size 7 (all the jubilee/hose clips are 7mm heads), slack it, rotate it, tighten it back up.

Took two of us to get the hose on to the elbow on the diverter – I had to push the hose on while Dad tightened up the clip, as the torque kept pushing the clip away from the elbow. A second pair of hands made it much easier.

Pump again. Hooray, no water dripping from the diverter valve output.

Wait.. why can we hear dripping?

Stuck my head in the hole with a torch, and Dad pumped. The Whale diverter valve (5606) gasket has failed, and water is coming out the body of the valve. Since I didn’t have one of these, and it was gone 5 pm, we called it a day.

I currently have no working head, and a shopping list of parts that includes a new seacock to screw in to the elbow, more Vetus hose, and a new Whale diverter valve.

Here endeth Sunday, insofar as the head is concerned.