Blue Opal’s anode is probably over a year old by now; I didn’t get it changed in Conwy, because it looked reasonable. With a year of growth on the hull too, I decided to bring her alongside our slip yesterday (the plan was for Saturday 10th, but I would have needed to slip her in the dark). Denis met me at the club for 9 am, and I brought her alongside quite easily – it was a lovely sunny morning, with not a breath of wind. By noon, I was able to start working on cleaning her hull off with a small garden hoe – the worst of the big plants had been hoed off a few weeks back. I ended up putting on my salopettes and seaboots, and just waded into the (damn cold) water to get the job done, so that I’d have the hull cleaned off by low water.

Unfortunately, I couldn’t get the hull clean enough for painting (nor did I have enough paint or time), and a bunch of the antifoul has come off with the pressure-washing that I did, so I’ll need to slip her again to get the hull fully cleaned and painted – I’ll have to find a bunch of victims to help me with that, because the underside of a 34 foot boat is pretty damn big. Doing under the hull on the side that’s towards the wall also needs someone shorter than me, and probably some good lighting – it’s dark under there, and the difference in light levels makes it pretty hard to see if you’ve cleaned the muck off.

A few more well-anchored, big plants had to be hoed off of the rudder, and I took the opportunity to remove some acorn barnacles that had made their home in space between the skeg and the rudder. With all that done, I could actually change the anode! Blue Opal has a through-hull stud setup for her anode; a size 18 socket on the end of a ratcheting socket wrench took care of the nut quite easily, and the washer came away nicely too. A few taps with a hammer, and the anode fell off too. It was at this point that I realised I had bought the wrong anode from the local chandlery (a 30 minute walk away), so I asked Denis if we had any spares in the boat house – lucky me, we did, and I traded my 100mm flat-backed anode for a 100mm anode with a cutout on the hull side of the anode, to fit around the stud fitting. Scraped and wire-brushed the old sealant from the hull, applied some Sikaflex to the back of the anode, on the area that makes contact with the hull, and on it went. Nut went back on easily, and the anode is done.

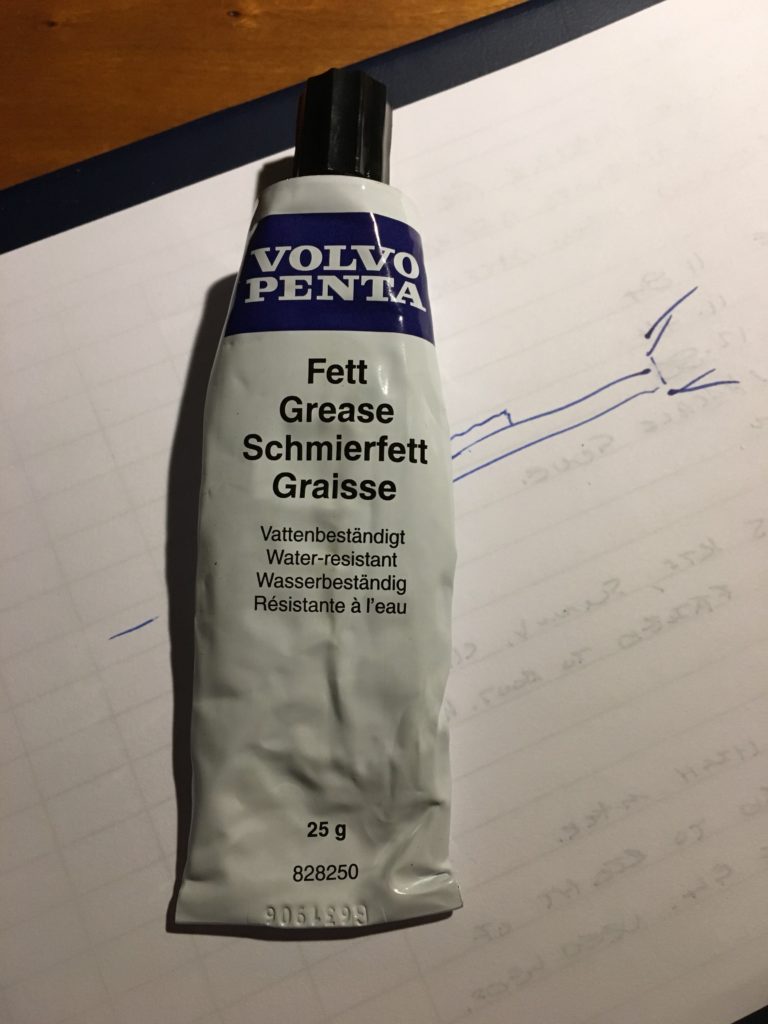

With a 3 pm low tide, it was going to be hours before she floated free. I had a committee meeting that evening, so a quick nip home for a late lunch, and back down to the club to get the grease injected in to the Volvo seal. Paraig (club boathouse assistant) agreed to go down the locker and into the engine bay. I’d done some research on how to get the grease injected, and it turns out that you can squirt the grease into a straw, slip the end of the straw into the seal, and squeeze the straw from the other end. This worked a treat.. well, I hope it did – the straw didn’t go in a long way, so it should have greased the right part of the seal! Can always chuck some more grease at it if things sound wrong.

While down the whole, Paraig noticed that the waterlock was rubbing on the jubilee clips that hold the Volvo seal in place. Some brainstorming, an attempt with a spare sail tie, and then an “ahah!” moment, and the waterlock is now tied up against the bulkhead that the hot tank pipes run through. The waterlock is still level, but it’s now suspended just enough to not hit the seal. I had noticed an interesting knocking sound recently, and had been worrying that the shaft was having issues. Moving Blue Opal last night, I didn’t hear the knock any more, but I’ll have to do a few loops around the inner harbour basin to be sure that the waterlock knocking against the hull/seal was what I heard.

Around 2030, I was able to burp the seal – got the biggest lump of long wood I could find (a shovel handle as it happens), and pressed down on the seal by reaching over the engine. There was a hiss, and then a gurgle, so I took that to mean that I’d bled the air out. I’ll probably do it again tomorrow morning before moving her out to the mooring, just to be sure.

Moving off of the slip and wall was an interesting affair – the wind had come up out of the south east, which pushed Blue Opal up against the wall. Ran a warp from the starboard midships cleat to the cleat on the far side of the pontoon, and back to the cockpit winch. Denis cast off the bow and stern for me, and I heaved on the warp to pull Blue Opal over. Engaged astern, and swung her out into the harbour. A slight “oops” happened here, as I cast off the bitter end of the warp, and as Blue Opal moved astern, the end got snagged on the pontoon cleat – I hadn’t noticed that there was a stopper knot in the end! Thankfully, Chris was on the pontoon still, and was able to free it quickly for me.

A bit of maneuvering later, and Blue Opal was snugly alongside the pontoon. The wind was useful at this point, as I just had to stop upwind of the pontoon, and drift sideways.