Friday

I took yesterday off, so that I could get more than just a weekend to tackle the works that needed doing. The yard had confirmed earlier in the week that the engine had been removed, so one loaded (remembered the latter this time) car and we were off to Malahide for breakfast. We passed through Screwfix in Swords on the way, and I picked up some stuff I’d ordered – boiler suit, mask, safety goggles, kneepads for the suit.

First order of the day was cleaning the engine bay a bit, and pulling off all of the old sound insulation. It wasn’t really bonded to the timber any more, and came away with barely a tug.

The boiler suit is going to be very useful given the state of the engine bay.

With all of the bits removed from the engine bay, and packaged up into take-away containers or a box, I was able to make a start on removing the linear drive. Someone else has been at this before, and replaced the R-clip with a bent-back split pin.

Interestingly enough, the linear drive arm is not installed according to the method detailed in the current installation instructions. Those instructions have the swivel bearing on the top side of the tiller arm, but in Blue Opal the pin was installed from the top down, with the drive arm coming up from below. I think it’s still within the 5 degree limit set down in the manual though, and I’ll might put the new one in the same way – will have to see what a correct-way-up installation does.

That pin was a right arse to get out, because I was working at the extension of my arms, and everything insisted on spinning and moving. Came out in the end though. I have to wonder if the upside-down installation contributed to the demise of the R-clip pin that should have been in there, as I suspect there’s not meant to be any load/rubbing on that clip.

Getting in and out of the bay to reach the linear drive is also a right pain – I’m not short, nor small, and it’s a pretty awkward space. I don’t want to lay down on top of the drive shaft either, as I’d like to avoid any accidental damage to the Vetus dual-lip seal that was installed in Pwhelli when the shaft tube was replaced. Thankfully K was on board as well, and could pass me bits and pieces while I worked in the bay and under the cockpit sole.

A few other bits and pieces got disconnected and tidied, but I’ve no photos of that from Friday.

Saturday

Today I went up to Malahide by myself, with the intent of doing some engine work. I was able to cross off a few items of work

- Taking the belts off

- Checking the water pump impeller (raw)

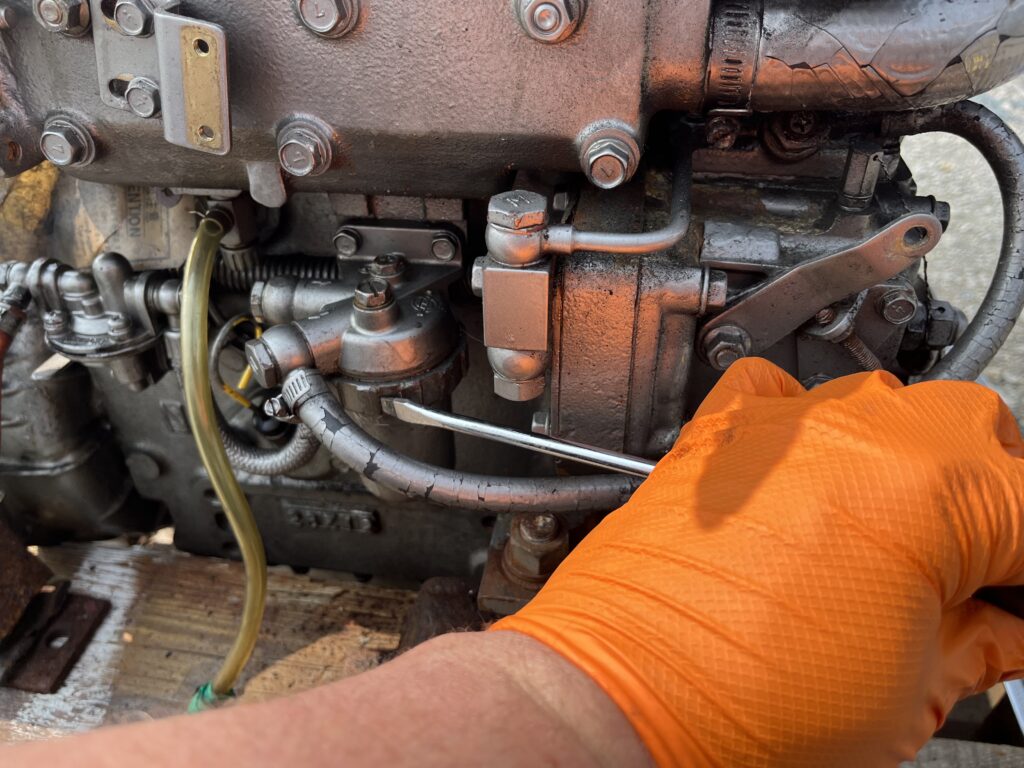

- Cleaned the bowl for the diesel filter

- Replaced the on-engine diesel filter

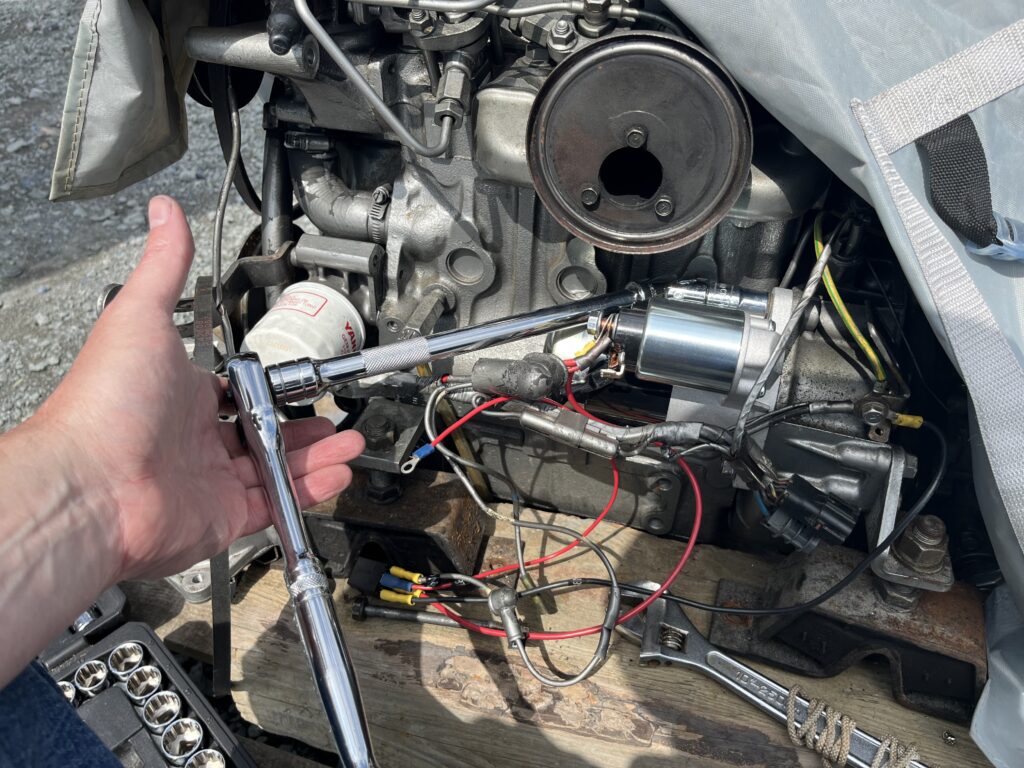

- Replaced the starter motor

I’m going to be putting a 10 micron filter between the 30 micron and the engine-based 10 micron filter, simply because I can’t get at the engine-based one when the engine is in position – it’s simply far too cramped to do the job. However, the existing filter on the engine should be changed anyway.

On the topic of the starter motor – the relay arrangement has resolved a lot of the problems with getting the engine to start, but I’ve still encountered occasional clicks with no movement of the starter. A replacement motor was not terribly expensive (though third party), and it just so happens that Marine Parts Direct was a 15 minute drive from Malahide.

Spent nearly an hour at MPD, because I was chatting about other bits they might be able to source for me. There should be a large replacement Treadmaster smooth fawn sheet arriving to the house soon – not a job for out of the water, but since they could get it for me, I opted to order it there and then for installation some time this year (acid landed on the existing installation).

Got the new starter motor on, started connecting the wires and discovered that the manufacturer (Recmar) uses a totally different size machine screw for one of the terminals. Said screw does not come with the starter motor. I don’t have any of an appropriate size, and I’m not even sure what size or pitch it is! (It’s about 4mm, but the screw pitch could be anything – I’m hoping it’s standard M4.)

I also spent some time today cleaning off the “glue” that molluscs use to hold themselves on to the hull, and took the shaft anode off. It wasn’t in bad condition, but it’ll get replaced anyway. While cleaning the “glue” off, I discovered damage to the starboard quarter under the waterline – I’ve asked the yard to investigate it for me.