The other day I discovered the single line reefing setup on Blue Opal had jammed in the reefed position; we were able to go sailing anyway, with the reef in, and it didn’t interfere with our sailing (other than reducing the sail power in the lighter airs that were present).

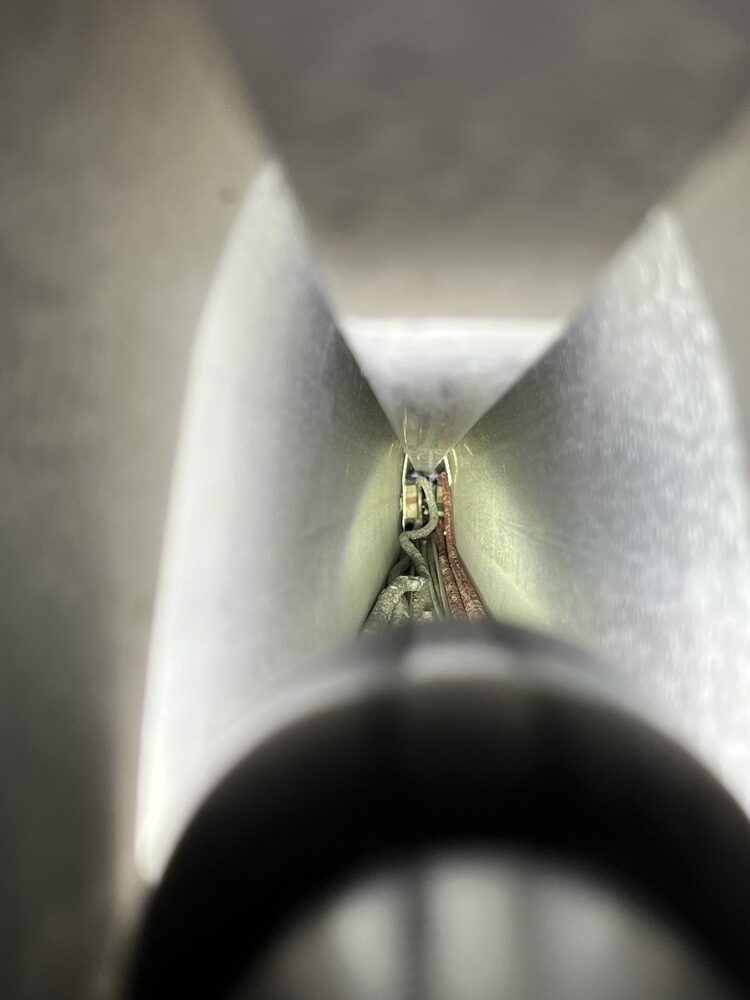

I figured something had jammed a block inside the boom, given the ropes pretty much refused to move. This necessitated taking the impact driver with T30 bits down to the boat, and carefully applying power to get the hammer impacts to free up the machine screws that fix the assembly at the outboard end of the boom to the boom itself (thankfully I didn’t have to go near the inboard end, that’s held on with Monel rivets!).

With some back and forth, and some sock wool and a needle from K (a knitting partner is great for things like this), I was able to get the whole assembly off and pull on the ropes until the internal bits slid out.

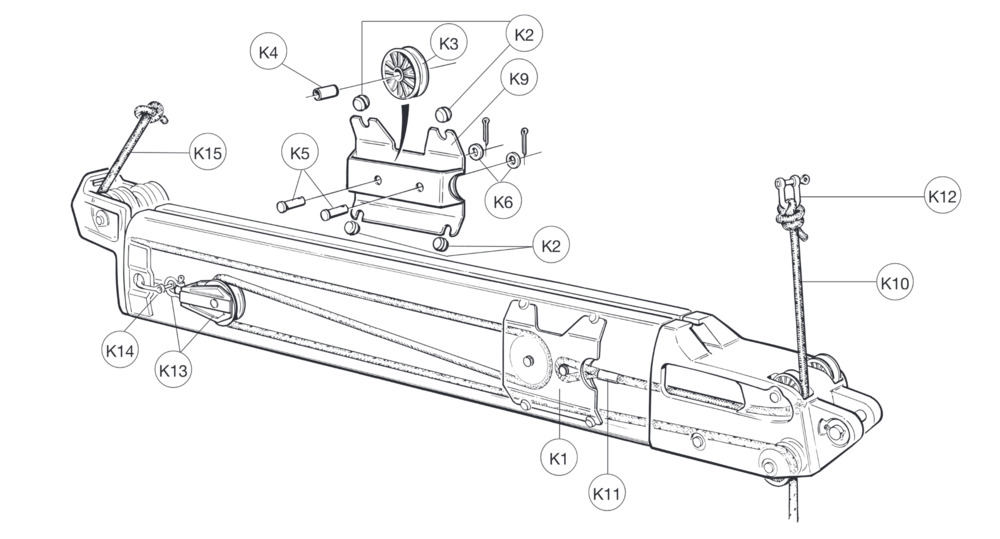

A word to the wise – be prepared to catch four very small plastic wheels when the assembly inside the boom pulls out. Have someone help by holding a bucket underneath the end of the boom, because they’re small and bouncy and will go down a cockpit drain faster than you can blink – no, that didn’t happen to me, but only because it bounced and missed by about 1 cm.

Given how much detritus came out, I think I’ll take the boom apart this winter, tip it vertical to get all the crap out, and rinse it out to get the bits that don’t fall out – that’ll give the wheels a smoother/cleaner surface to run on. I’ve also seen mention of straightening the internal assembly a bit to make it just that little tighter to the channels; this apparently makes them move more smoothly.

Anyway, the reefing line had come right off of the sheave, and jammed between the sheave and the metal framework that the sheave sits in. It had jammed so hard that the stainless steel was bent out of shape. Some tugging later, and levering with a screwdriver, and the line was back where it needed to be. A rubber mallet and some percussive maintenance and the stainless steel is mostly back into shape.

Of course, in putting it all back together, I’ve managed to jam one of the reefing lines on the outhaul line, so now I have to take it all apart again and try to keep tension on all of the lines while I insert the boom end back into place. Needs about 3 people and 7 hands to get it done I think.

Seldén’s PDF documentation for a 2007 and earlier boom shows that the metal frame (K9 / K1) is just called a “block”, and for the model number stamped into mine (538-854), the sheave (K3) is ø57/12-13. Those are easy to find, and given the damage to the port side sheave, I’ll probably pull the starboard block out and check the state of the sheave to see if I’m ordering two.

What I can’t find is the actual block assembly; I’ve sent an email off to Seldén to find out if they even have those block frames in stock, and if not, can I please have the CAD diagrams to send off to a machine shop. If I can’t get either a new frame or the diagrams, I’ll have to make up my own drawings (using FreeCAD or similar) and get one made from that. If I end up going that route, I’ll probably look at modifying the assembly to have a curved brace that would anchor the middle of the span, placed between the two holes for the clevis pins (K5).