As mentioned in a previous post, Blue Opal has had issues with the starter motor for several years – turn the switch, press the button, and nothing more than a click is heard from the solenoid. It’s intermittent, but I’d prefer to know that the engine will turn over on the first push.

A proposed solution is to use a relay activated by the push button to pass the current to the solenoid by using short “local” wires. The relay is connected to the solenoid and battery terminal with a short bit of mid-weight tinned cable (I think I used something larger than 2.5mm square), and the actuation side is connected to the common ground bolt on the back of the engine where the harness attaches and to the harness.

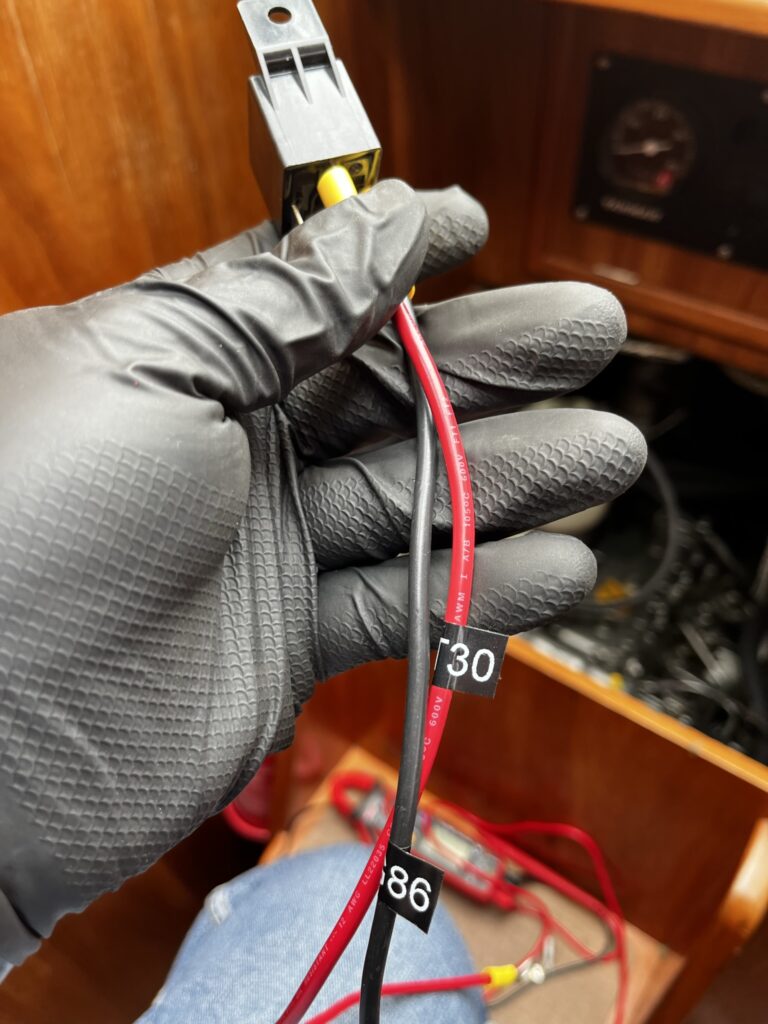

The instructions I was following came from Salt Water Diesels (bottom of the page). In short, “85 & #86 actuate the relay and #30 & #87 power the solenoid”.

The whole process took me about an hour and a half, a good 30 minutes of which was planning how to get access to the starter motor and what the sequence of operations should be. I started by taking the intake filter off (and discovered I need a new filter somewhat urgently – the current one’s foam is falling apart), moving a heating hose out of the way, and taking a photograph of what was there so I could revert easily if needed.

It was also very confusing to do a continuity test on both sides of the button and hear tone. That was weird, and I haven’t yet worked out what was going on there. It’s like the button was pressed, but it wasn’t, and it wasn’t trying to start the engine either at that point. One for another day; disconnecting one side of the button from the power switch broke the continuity (and gave me confidence to work on the wiring, because now I couldn’t start things accidentally (and the main engine battery switch was off too)).

A good 10 minutes or more was spent finding what cabling I had that would match up with the crimp ends. I ended up using the largest connectors for most of the work; the yellow ones. Thankfully my supply of them is pretty good, with two different sizes of spade female.

The rest of the time was spent bending over the engine trying to get various fastenings loosened without dropping screws, bolts, nuts, or washers; stripping wire and crimping ends (and re-crimping when the end pulled off easily); labelling the various cables (because there are 3 red ones and a black one); and then putting all the fastenings back in place. It did not help that I didn’t have a stubby screwdriver on board for the screw that the white wire was attached to – improvised with a screwdriver bit and adjustable wrench.

It would have been good to have a wire brush to clean the terminal surfaces, but I don’t, so that’ll happen another day.

The patient survived the experience, and turned over immediately. This is not proof that the problem is fixed; the engine has turned over on first push before. A clamp meter registered about 10 amps; I need to measure the diameter of the original wire in the harness, but I don’t think it was much past 2.5 square mm for a 3+ metre run, plus whatever length it traversed for the return. That should have been ok, but the harness is also 25 years old, so it may have increased resistance.

Anyway, the rest of the season will tell me if this solution worked properly. If there are no more “push button, click” occurrences, then the solution is correct. If it doesn’t solve it, then the starter motor is going to need checking.

Oh, and the replacement starter key switch has been installed too. I used an OEM part, but if it ever breaks again, I’m finding a cheaper option. 100 EUR for a key switch is nuts.