The new alternator has been squeaking at low revs, and by the alternator, I mean the alternator belt.

I had initially shimmed the top mounting bracket with a penny washer that I drilled out with a 10mm bit to make it fit. This is the configuration I was using when I first heard the squeak.

Put a straight edge across the pulleys, and noticed that the alternator was maybe a bit proud of the other pulleys. So, took it all to bits, and moved the shim to the back of the bracket (and it has to sit between the bracket and the ears on the alternator, because that’s where the gap is). This was a right pain to do, because there’s a coolant hose that runs right over where the washer needed to slot in to, forcing me to come at it from the side, and then use a small bolt to lever it from the rear side of the fitting to get it to sit so that the big bolt would go through it.

This didn’t improve the squeak at all; in fact, it may have made it worse.

While sitting off of Dalkey Island this morning, I decided to try a thinner shim, and back in the front position on the bracket. This was easy enough to do, unlike the rear position. Removed the bolt, removed the penny washer, and slotted a thinner washer in.

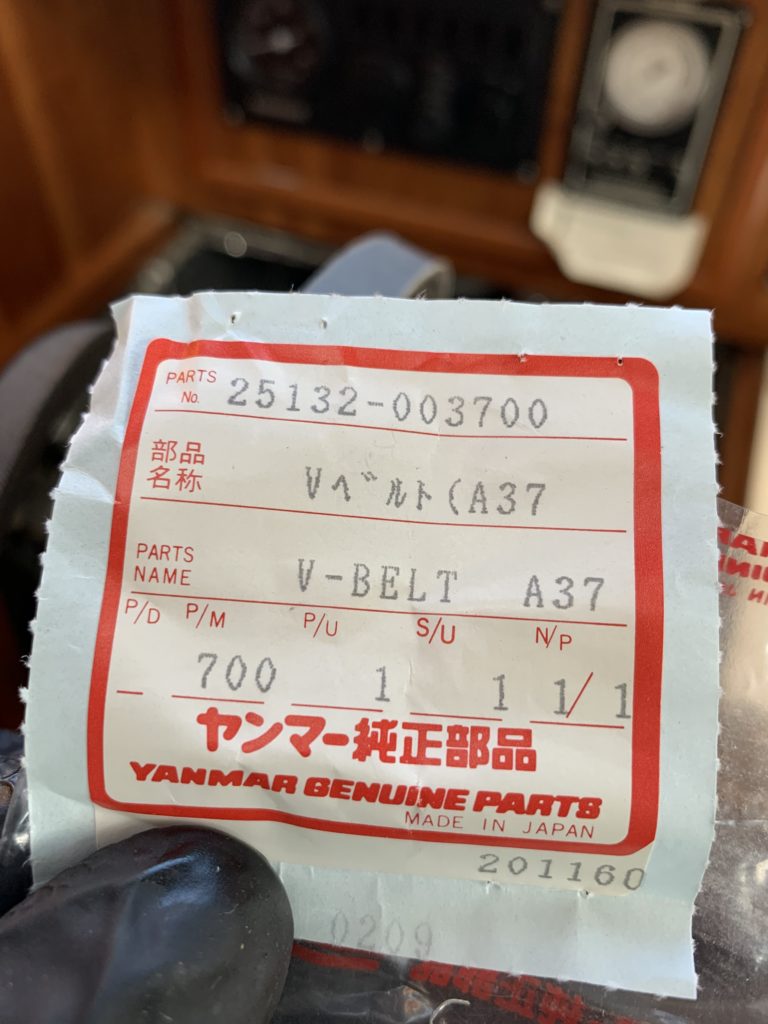

Looking at the pulleys, they’re all showing paint removal, and shiny metal – even the brand new alternator pulley (which was black). I dug into the spares cabinet, and hauled out the replacement alternator belt. It’s a good 3 – 4 mm wider than the existing one, so I decided to change it out at the same time.

This led to an interesting problem – even with the alternator slacked off completely on the mounting bracket, the belt refused to go around all three pulleys. The new alternator, while being listed as a replacement for the LR155-20B, is just that bit bigger and had to be installed in a different position from the old one. The old belt had enough shaved off of it that it would fit around easily.

Threw the decompression levers, got the belt on to the fresh water pump and the alternator pulleys, and started on the shaft pulley. Grunting and some brute force got the shaft pulley to turn, taking the belt with it. With the belt on, it was time to get the alternator back in to position so that the belt tension was correct(ish) and the alternator wasn’t resting on part of the engine. A bit more grunting and heaving, while simultaneously (with my third hand.. wait, no, I don’t have three hands, more’s the pity) using a spanner blind on the bracket machine screw got the alternator locked back in place, with about 2 mm clearance from the engine. It used to have about 2 cm clearance!

Motored back to the mooring, as the anchorage at Dalkey was becoming uncomfortable, and the belt has not squeaked at all.